Quality Inspection for Aramid Fabric - Aramid UD BulletProof Ballistic Fabric – Linry

Quality Inspection for Aramid Fabric - Aramid UD BulletProof Ballistic Fabric – Linry Detail:

Quick Details

Place of Origin:Jiangsu, China

Brand Name:Linry

Type:Aramid

Color:Yellow

Size:1.6*200m

Application:Ballistic Protection

Suitable for:BulletproofVest/Plate/Helmet/Vehicle

Fabric:Aramid UD

Feature:Light Weight

Certificate:ISO9001

Thickness:0.2MM

200g/260g Bullet Proof Ballistic Aramid Fabric

Aramid bullet proof fabric, it has soft and light, anti-UV features. Widely used in inner core soft armor panel for bulletproof vest, hard armor panel for plate, bulletproof shield, explosion-proof blanket.

Aramid UD cloth is a composite material made by impregnating aramid fiber in a resin matrix. Two or more layers of unidirectionally arranged fibers are orthogonally combined into a continuous sheet-like coil by 0°/90°. The product is soft, wear-resistant and impact resistant, and is widely used in soft body armor and bulletproof helmets.

| Model | Area Density | Size | Layer number of different levels | |

| NIJ IIIA 9mm | NIJ IIIA .44 | |||

| LR70 | 110g/m2 | 1.6mx3.2m

(Piece) 1.6mx200m (Roll)

|

42 | 55 |

| LR70 | 125g/m2 | 37 | 45 | |

| LR70 | 160g/m2 | 28 | 34 | |

Make of high performance aramid sewing thread, it has high strength, high modulus, heat resistance, acid and alkali resistance, light-weight, insulating, anti-aging and long life cycle and flame resistance features. Widely used in inner core soft armor panel for bulletproof vest, hard armor panel for plate, bulletproof shield, explosion-proof blanket

Application: Soft armor panel.

Specifications: Area density can be Customized.

| Model | Material | Area Density | Size | Layer number of different levels | |

| NIJ IIIA 9mm | NIJ IIIA .44 | ||||

| C03200Y | high performance aramid sewing thread | 200g/m2 | 1.6×3.2m

(Piece) |

24 | 26 |

| C03220Y | high performance aramid sewing thread | 220g/m2 | 24 | 28 | |

Properties

1. Good resistance to abrasion

2. Good resistance to organic solvents

3. Nonconductive

4. No melting point, degradation starts from500℃

5. Low flammability

6. Good fabric integrity at elevated temperatures

7. Prone to electrostatic charge build-up unless finished

8. High Young’s modulus

9. High tenacity

10. Low creep

11. Low elongation at break

Product detail pictures:

Related Product Guide:

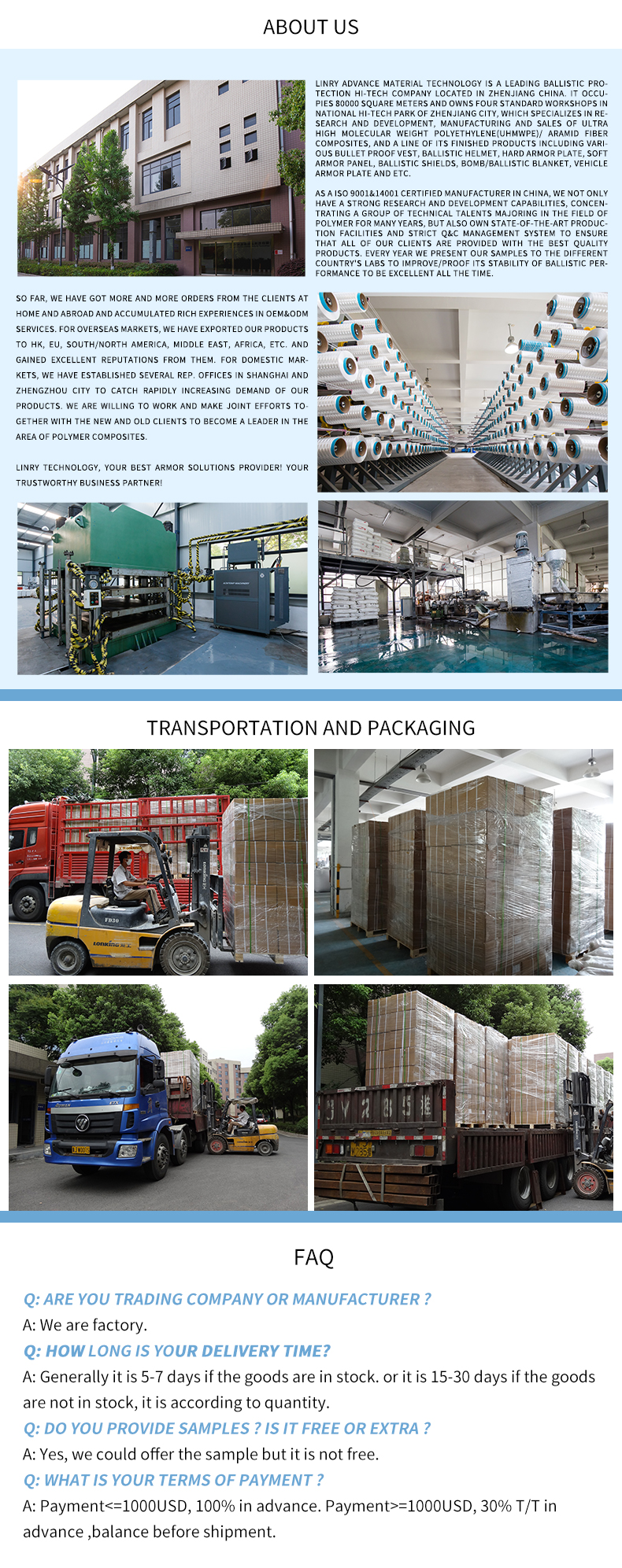

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for Quality Inspection for Aramid Fabric - Aramid UD BulletProof Ballistic Fabric – Linry , The product will supply to all over the world, such as: Australia, Korea, Serbia, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.